technology

imaging from top to bottom

We look after printing houses when creating innovative solutions, mainly based on colour and image processing, as well as on colour control and stabilization in continuous production.

In our work, every element is important, from the entry of the image and its registration, through digital transformation to printing form, to the printing itself. In short – screening, colour and its control, selection of appropriate inks and control of printing devices so that they transfer to the target surface the exact data Client wants.

EM founder and chief technologist – Marcin Dąbrowski – has experience in working in research and development centers in creating new printing technologies and developing ongoing ones. He deals with imaging and creates specialized printouts that meet various clients’ expectations. Scientifically he’s researching colour.

specialisations

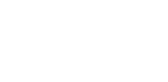

colour

screening

Selecting the right screen from the predefined ones and creating your own custom made screens for the best effect.

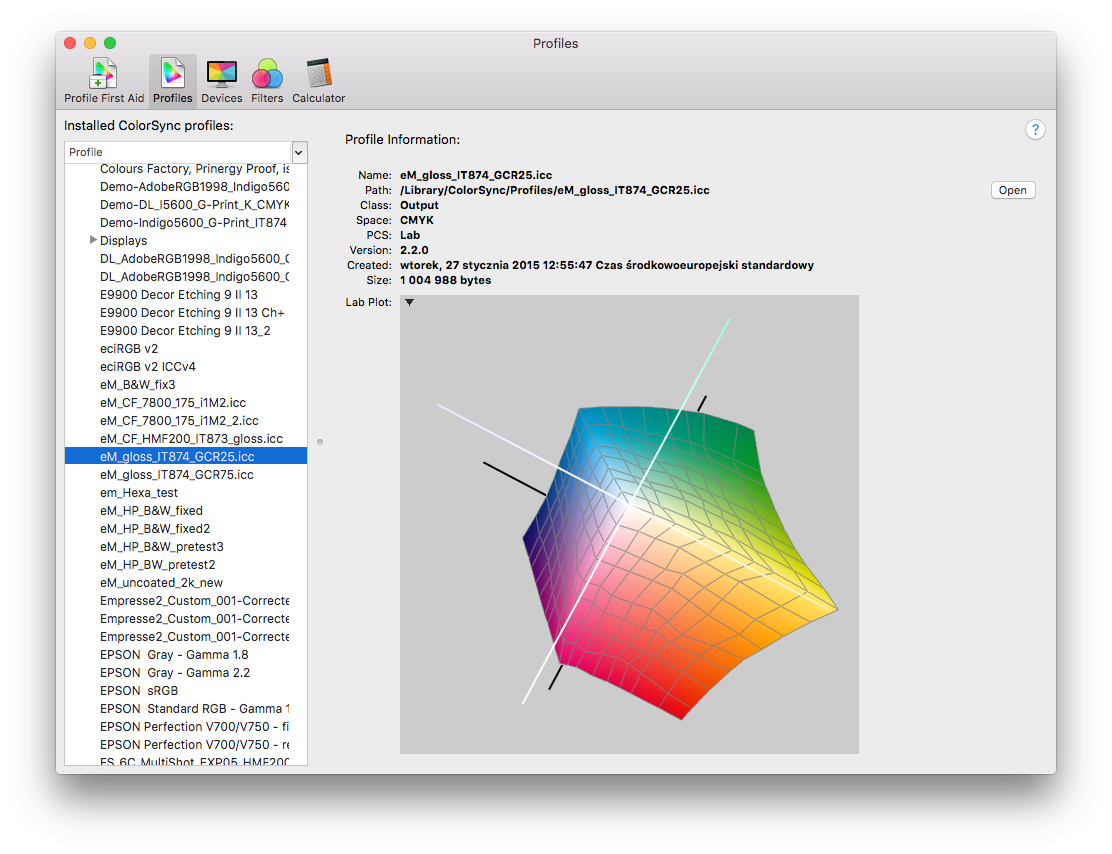

additional colours

ECG, Pantone, Hexachrome, hi-fi, flu, duotone, tritone … CMYK as well, but which one?

We mix paints for HP Indigo, create new CMYK spaces, expand gamuts in a specific direction.

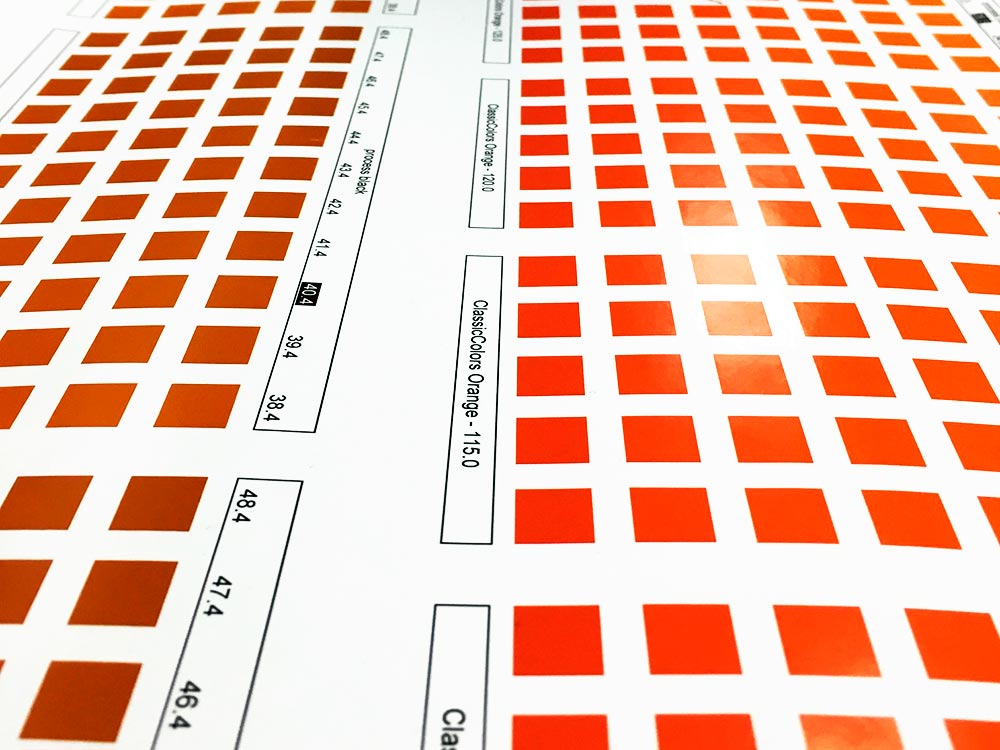

research and development – R&D

Analysis of hardware and software configurations and their development for equipment manufacturers.

Technology creating and research conducting for companies for EU projects.

digital workflow

Basic activities increasing productivity and accuracy of implementation – minimizing file processing to maintain the highest quality and selecting the right steps, as well as optimizing their number per order.

workflow

high-speed inkjet

Color configuration with limited ink consumption (low TIL / TAC), standardization, ripping with other printing systems like offset and digital printing.

HP Indigo

Work with colour, crew training in the use of equipment and technology consulting.

Marcin has 2 years of experience as an R&D engineer in the HP Indigo Division in Israel. He is the author of commercialized LLK as well as 5 and 7 colour printing. He has many years of experience in servicing machines from series 2, 3 and 4.

quality offset printing